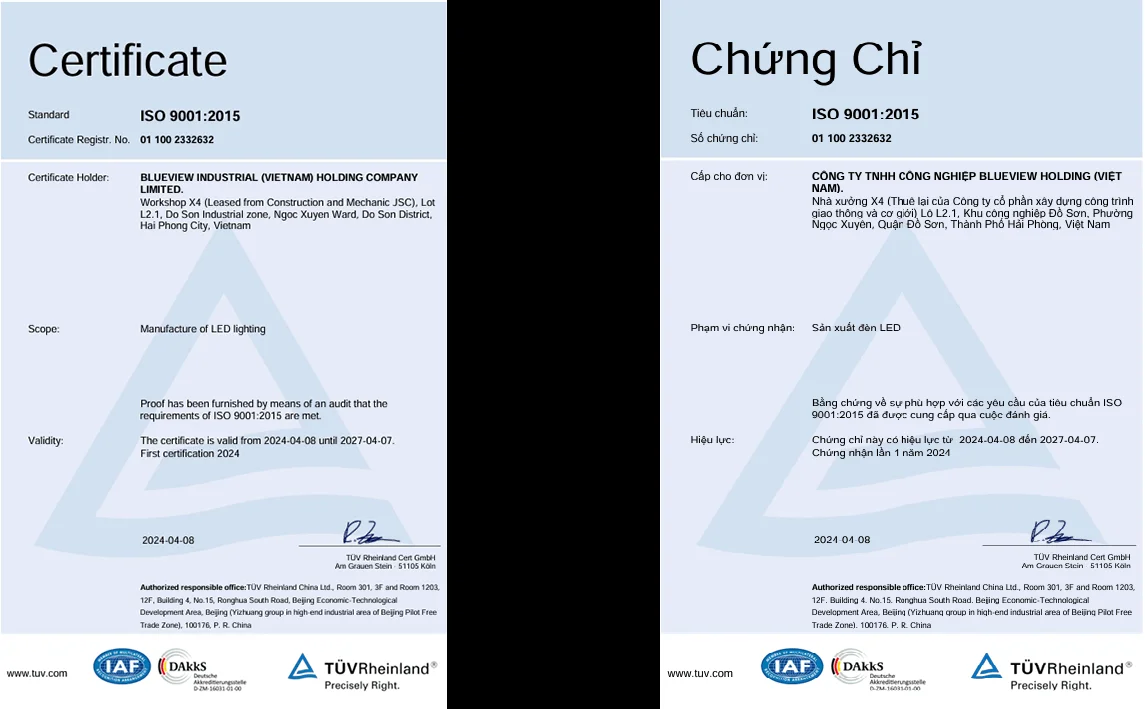

Blueview Vietnam Production Base

Blueview’s Vietnam Production Base, officially launched in August 2023, represents a significant milestone in the company’s global manufacturing strategy. Located in Hai Phong — Vietnam’s second-largest port city — this modern facility covers 2,700㎡ and is equipped with advanced automated production lines. Operated by a professional quality management team from Blueview headquarters and over 100 trained local workers, the factory combines global standards with localized efficiency.

The Vietnam base is capable of producing a wide range of high-performance LED products, including LED strip lights, LED modules, LED rigid bars, and Neon Flex solutions. From decorative lighting to architectural and signage applications, Blueview Vietnam delivers consistent product quality, rapid lead times, and flexible customization — offering comprehensive solutions tailored to your every application need.